CAD Blocks categories

3D models

3D models home furniture

home furniture sanitary ware - bathrooms

sanitary ware - bathrooms professional equipment

professional equipment doors and windows

doors and windows people and animals

people and animals plants and trees

plants and trees vehicles - transports

vehicles - transports architectural details

architectural details mechanical - electrical

mechanical - electrical urban planning - civil works

urban planning - civil works safety health construction

safety health construction accessible design

accessible design drawing sheet

drawing sheet signals

signals construction machinery

construction machinery accessories and objects

accessories and objects maps and street maps

maps and street maps

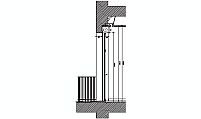

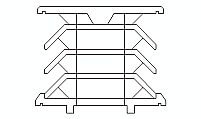

Typical Bathroom Plumbing Scheme CAD Block

size: 50 kb

category: electrical, mechanical and HVAC

related categories:

description: CAD drawing of a typical bathroom plumbing scheme, including labeled water supply lines for hot and cold water, valve placements, and fixture connections for a standard bathroom layout.

file extension: .dwg CAD - AutoCAD software

Features, Dimensions, and Applications of a Typical Bathroom Plumbing Scheme

Essential Components and Layout of Bathroom Plumbing

This design represents a standard water distribution layout for residential and small commercial bathrooms. It includes:

- 1. Cold Water Line: Supplies water to the toilet, sink, and shower, indicated by blue piping.

- 2. Hot Water Line: Delivers heated water to the sink and shower, marked in red for clarity.

- 3. Valves: Positioned at the water entry points for easy flow regulation and maintenance access.

- 4. Fixtures: Includes plumbing connections for a toilet, sink, and shower, designed for straightforward installation.

- 5. Piping Alignment: Positioned at 6'-10 3/4" (2100 mm) above the finished floor for efficiency and accessibility.

Each element is precisely configured to optimize water flow, reduce installation time, and comply with international standards.

Fixture Heights and Piping Dimensions

The CAD design provides accurate measurements, ensuring compatibility with standard fixture setups. The key dimensions include:

- Piping Height: 6'-10 3/4" (2100 mm) above the floor.

- Toilet Connection: Cold water supply set at 12 inches (305 mm) from the floor.

- Sink Connections: Hot and cold water inlets positioned at 24 inches (610 mm).

- Shower Connections: Mixing valve at 48 inches (1220 mm), showerhead at 72 inches (1830 mm).

These dimensions align with industry codes such as the Uniform Plumbing Code (UPC), ensuring safe and efficient installation.

Answers to Common Plumbing Questions

- Why are water lines color-coded?

- Color coding simplifies installation by visually distinguishing between hot and cold water lines. In most countries, blue is universally used for cold water and red for hot water, as per standards like the UPC (Uniform Plumbing Code) in the US, BS EN 806 in Europe, and JIS G3442 in Japan. This prevents cross-connections during installation. For example, in North America, hot water pipes must be installed on the left-hand side of fixtures, while cold water is on the right-hand side. In the UK and Asia, this is similar but may vary slightly for localized systems. Pipe diameter recommendations include 1/2-inch (13 mm) or 3/4-inch (19 mm) for residential water supply lines, ensuring efficient flow rates and temperature control.

- What materials are commonly used for pipes?

-

Common plumbing materials vary by region, but PEX, CPVC, and copper are widely used due to their durability and compliance with regulations. For example:

- USA and Canada: PEX pipes dominate residential plumbing due to flexibility and resistance to freezing. Copper is used for high-temperature systems as per ASTM B88 standards.

- Europe: Multilayer pipes (PEX/AL/PEX) and copper are common, regulated by EN 1057 for copper and ISO 22391 for PEX.

- Japan: Stainless steel and PEX are preferred for durability under JIS G3442 standards.

- Asia: CPVC is common in tropical climates due to its resistance to high humidity.

- Why are valves included in the design?

-

Valves provide critical control points for isolating water supply during maintenance or emergencies. In North America, ball valves or gate valves are mandatory at the main water entry point, adhering to UPC and IPC codes. These must be installed at accessible heights, typically 4-6 inches (100-150 mm) above the floor or above ground for outdoor installations.

In Europe, regulations like BS 6700 mandate valves at every branch or fixture connection. Japan and Asia require localized shutoff valves near sinks and toilets under JIS G3442. Key valve types include:

- Ball valves for durability and quick shutoff.

- Stop valves near fixtures for localized control.

- Pressure-reducing valves to maintain system pressure, particularly in high-rise buildings.

- What standards does this design follow?

-

This plumbing design complies with global standards to ensure safety, efficiency, and compatibility. In the US, the UPC and IPC codes govern pipe sizing, materials, and layouts, requiring water lines to be spaced at least 6 inches (150 mm) apart to avoid thermal interference. In Europe, BS EN 806 requires minimum pipe slopes of 1% for drainage systems. In Japan, JIS G3442 mandates specific pipe coatings for corrosion resistance. Canadian plumbing systems follow the NPC (National Plumbing Code), which emphasizes insulation for pipes in cold climates.

Each region also has specific standards for pipe diameters:

- Main supply: 1-2 inches (25-50 mm).

- Branches: 3/4-inch (19 mm).

- Fixture connections: 1/2-inch (13 mm).

- Can this scheme be modified for larger spaces?

- Yes, this scheme is highly adaptable. In larger spaces or complex layouts, additional fixtures like bidets, secondary sinks, or dual shower systems can be incorporated. Pipe sizes may need to increase for higher flow rates, with diameters of up to 3 inches (76 mm) for main supply lines in commercial or multi-unit buildings. Larger systems often use additional branch lines with strategic placement of valves to isolate sections for easier maintenance. Standards like BS 806 and IPC recommend keeping supply lines within 50 feet (15 m) of fixtures to avoid pressure loss and temperature drops. Regional codes, such as the NPC in Canada or JIS G3442 in Japan, may specify additional insulation or pressure requirements for large-scale designs.

Benefits of a Standard Bathroom Plumbing Layout

This well-organized plumbing design simplifies installation and future maintenance. Its thoughtful layout includes features like color-coded piping for error-free connections and accessible valves for enhanced safety and control.

Standardized dimensions make it compatible with most bathroom fixtures, while the modular nature allows flexibility for residential and small commercial setups. This layout saves time and ensures compliance with global plumbing standards.

A Brief History of Bathroom Plumbing

Plumbing systems have evolved dramatically, transitioning from basic gravity-fed pipes to highly efficient pressurized systems. Modern materials like PEX and PVC have replaced older materials like clay and lead for durability and safety.

Innovations like modular piping systems and integrated valve designs have enhanced efficiency and safety. Leading manufacturers now ensure compliance with global standards, making these systems versatile and adaptable to various layouts.