CAD Blocks categories

3D models

3D models home furniture

home furniture sanitary ware - bathrooms

sanitary ware - bathrooms professional equipment

professional equipment doors and windows

doors and windows people and animals

people and animals plants and trees

plants and trees vehicles - transports

vehicles - transports architectural details

architectural details mechanical - electrical

mechanical - electrical urban planning - civil works

urban planning - civil works safety health construction

safety health construction accessible design

accessible design drawing sheet

drawing sheet signals

signals construction machinery

construction machinery accessories and objects

accessories and objects maps and street maps

maps and street maps

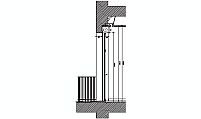

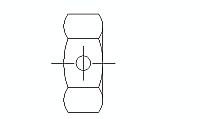

Concrete Masonry Unit - CMU Block DWG File

size: 14 kb

category: architectural details

related categories:

description: Horizontal CAD section of a Concrete Masonry Unit featuring two hollow cores, commonly used for construction and reinforcement purposes. This block has dimensions of 15.625 inches in length, 5.2625 inches in width, and 7.625 inches in height (39.7 cm in length, 13.4 cm in width, and 19.4 cm in height).

file extension: .dwg CAD - AutoCAD software

Explore the Key Features of CMU Blocks in Construction

Detailed Overview of Concrete Masonry Units

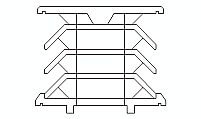

Concrete Masonry Units (CMUs) are rectangular building blocks made of Portland cement, aggregates, and water, widely used in construction. The block described here includes two hollow cores, designed to enhance structural stability and reduce material usage. This specific block has dimensions of 15.625 inches in length, 5.2625 inches in width, and 7.625 inches in height (0.397 meters, 0.134 meters, and 0.194 meters respectively). The hollow cores allow for the integration of reinforcement bars and concrete grout, adding strength for load-bearing applications.

CMUs like this one are commonly available in various configurations, including solid and multi-core designs. These blocks are widely used in both load-bearing and non-load-bearing walls, with standard dimensions such as 8x8x16 inches and 12x8x16 inches, making them versatile for numerous architectural and structural designs.

Common Dimensions of CMUs in Construction

The standard dimensions of CMUs vary depending on regional construction standards. In the U.S., nominal dimensions range from 8x8x16 inches to 4x8x16 inches (20.32x20.32x40.64 cm to 10.16x20.32x40.64 cm), with mortar joints of 3/8 inches (10 mm). European blocks are commonly metric, such as 200x200x400 mm (7.87x7.87x15.75 inches), while Asian blocks are adapted to local practices, with similar dimensional standards.

The block described here fits within the range of typical CMU dimensions and follows industry standards like ASTM C90 for load-bearing units. These measurements allow compatibility with other modular systems and ease of construction in architectural and structural applications.

Construction Techniques Using CMUs

- What is the typical mortar joint size for CMU walls?

- The standard mortar joint size is 3/8 inches (10 mm) for both vertical and horizontal joints, ensuring stability and uniformity.

- How are CMUs reinforced?

- Reinforcement is typically done by inserting steel bars into the hollow cores and filling them with concrete grout.

- What is the maximum recommended panel size for unreinforced CMU walls?

- Unreinforced panels are generally limited to 144 square feet (13.4 m²) to prevent cracking due to structural or thermal stresses.

- Do CMUs require surface treatments?

- CMU walls can remain unfinished or be covered with cement mortar, stucco, or paint for added durability and aesthetic appeal.

- What materials can be combined with CMUs?

- CMUs are often paired with brick veneers, insulation panels, and concrete columns to improve performance and visual design.

Advantages of CMUs in Modern Construction

Concrete Masonry Units are renowned for their high compressive strength, fire resistance, and thermal efficiency. They are a cost-effective and modular option for building walls, offering quick assembly and adaptability to a variety of structural needs. Reinforced CMUs are particularly valuable for load-bearing applications in both residential and commercial projects.

CMUs are also highly sustainable, as many manufacturers incorporate recycled materials into their production. They provide excellent soundproofing, are resistant to pests, and can be finished with a variety of textures or coatings, such as split-face designs or smooth surfaces for painting.

History and Global Standards for CMUs

Concrete Masonry Units originated in the early 20th century as a more durable and modular alternative to traditional clay bricks. Over time, innovations such as hollow cores and lightweight aggregates have enhanced their functionality. Global standards, including ASTM C90 (U.S.), BS 6073 (UK), and IS 2185 (India), regulate their production to ensure quality and performance.

While CMUs are universally used, their designs and standards vary worldwide. For example, European blocks often prioritize thermal insulation, while Asian manufacturers adapt designs to seismic requirements. This flexibility ensures CMUs remain a cornerstone of modern construction globally.