CAD Blocks categories

3D models

3D models home furniture

home furniture sanitary ware - bathrooms

sanitary ware - bathrooms professional equipment

professional equipment doors and windows

doors and windows people and animals

people and animals plants and trees

plants and trees vehicles - transports

vehicles - transports architectural details

architectural details mechanical - electrical

mechanical - electrical urban planning - civil works

urban planning - civil works safety health construction

safety health construction accessible design

accessible design drawing sheet

drawing sheet signals

signals construction machinery

construction machinery accessories and objects

accessories and objects maps and street maps

maps and street maps

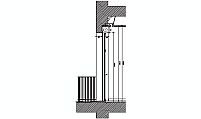

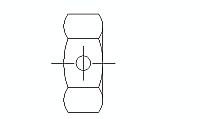

Fire Hydrant Design: Front Elevation in CAD

size: 7 kb

category: electrical, mechanical and HVAC

related categories:

description: detailed front elevation view of a fire hydrant showing key components such as the bonnet, outlet valves, and barrel.

file extension: .dwg CAD - AutoCAD software

Technical Features, Dimensions, and Standards of Fire Hydrants

Technical Description of the Fire Hydrant

The fire hydrant depicted in this CAD drawing features a robust and standard design suitable for urban firefighting systems. The hydrant comprises three main sections: the bonnet (top cap), the barrel (central cylindrical body), and the base (flanged connection to underground pipes). The bonnet typically houses a pressure relief valve to prevent overpressure.

On the side, the hydrant includes outlet valves, often sized at 2.5 inches or 4.5 inches in diameter, compatible with fire hoses. These valves are sealed with caps to prevent contamination. The barrel is reinforced to withstand high water pressure, while the flanged base ensures a secure connection to the underground water supply network.

Dimensions and Material Specifications

The typical height of a fire hydrant ranges between 30 to 36 inches (approximately 76 to 91 cm) above ground, depending on regional requirements. The barrel diameter is usually around 6 inches (15 cm), with outlet valves sized at 2.5 inches and 4.5 inches to accommodate standard firefighting hoses.

The hydrant is constructed from ductile iron or cast iron, ensuring durability and resistance to weathering and mechanical stress. The interior is coated with epoxy to prevent corrosion, while the exterior features a powder-coated finish for visibility and additional protection.

Standards and Compliance for Fire Hydrants

- What safety standards do fire hydrants follow?

- Fire hydrants in the U.S. comply with AWWA C502 standards for dry-barrel hydrants and NFPA 291 for water flow requirements.

- What are the color codes on fire hydrants?

- Hydrants are color-coded to indicate water flow capacity. For example, red indicates less than 500 GPM, while blue indicates 1500 GPM or more.

- What is the typical operating pressure?

- Hydrants are designed to operate at pressures ranging from 20 to 120 psi, depending on the water supply system.

- What maintenance is required?

- Regular inspections and lubrication of outlet valves and the bonnet are recommended to ensure optimal performance.

- Are these hydrants freeze-resistant?

- Yes, many hydrants feature a dry-barrel design to prevent freezing in colder climates.

Advantages of Modern Fire Hydrant Designs

Modern fire hydrants offer significant advantages in terms of durability, efficiency, and safety. The use of ductile iron or cast iron ensures longevity, while interior and exterior coatings provide protection against corrosion and environmental damage.

Additionally, these hydrants are equipped with pressure relief mechanisms to prevent damage during high-pressure surges. Their standardized connections make them compatible with a wide range of firefighting equipment, ensuring quick and effective response during emergencies.

Evolution and Global Standards for Fire Hydrants

The fire hydrant has evolved since its introduction in the early 19th century. Early designs featured wooden barrels and basic valves, while modern hydrants utilize advanced materials and engineering for improved functionality. The dry-barrel hydrant, commonly used in colder regions, prevents freezing by keeping the main valve below ground.

Global standards like ISO 9090 in Europe and CSA B70 in Canada ensure compatibility and safety across various regions. These standards focus on durability, water flow efficiency, and environmental resilience, making fire hydrants a critical component of urban infrastructure worldwide.