CAD Blocks categories

3D models

3D models home furniture

home furniture sanitary ware - bathrooms

sanitary ware - bathrooms professional equipment

professional equipment doors and windows

doors and windows people and animals

people and animals plants and trees

plants and trees vehicles - transports

vehicles - transports architectural details

architectural details mechanical - electrical

mechanical - electrical urban planning - civil works

urban planning - civil works safety health construction

safety health construction accessible design

accessible design drawing sheet

drawing sheet signals

signals construction machinery

construction machinery accessories and objects

accessories and objects maps and street maps

maps and street maps

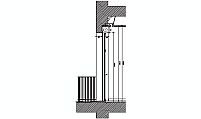

Steel Nut Side View - DWG CAD Design

size: 4 kb

category: architectural details

related categories:

description: Front elevation of a steel nut in CAD format, showing a hexagonal design with a circular threaded opening for bolts.

file extension: .dwg CAD - AutoCAD software

Dimensions, Standards, and Uses of Steel Nuts

Overview of Steel Nut Design and Features

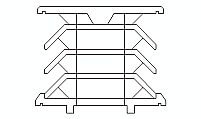

Steel nuts are essential fasteners in the construction and engineering industries. The nut shown in the image features a hexagonal outer design for easy gripping with tools and a circular central threaded opening to accommodate bolts. This shape ensures optimal torque application and even stress distribution during use.

Steel nuts are typically paired with bolts of matching thread sizes and are used to secure structural components. Their design ensures durability and resistance to shear and tensile forces, making them indispensable in heavy-duty applications such as steel structures, machinery assembly, and bridge construction.

Common Dimensions and Standards for Steel Nuts

The dimensions of steel nuts vary depending on their application and regional standards. In the U.S., steel nuts commonly adhere to ANSI/ASME B18.2.2, with sizes ranging from 1/4 inch to 2 inches in diameter. In Europe, the DIN 934 and ISO 4032 standards regulate hex nuts, with sizes typically measured in millimeters, such as M6 to M64. In Asia, countries like Japan follow the JIS B 1181 standard for similar specifications.

For smaller precision applications, nuts can range from 6 mm (M6) to 20 mm (M20), while larger applications may require sizes exceeding 50 mm (M50). The threading is standardized to ensure compatibility with bolts and washers manufactured under similar guidelines.

Torque Specifications and Installation Guidelines

- What is the recommended torque for tightening steel nuts?

- Torque values depend on the size and grade of the nut. For example, a Grade 8 steel nut with a diameter of 1 inch typically requires 250-300 ft-lbs of torque.

- Are washers required during installation?

- Washers are recommended to evenly distribute the load and prevent damage to the surface beneath the nut.

- How do you prevent loosening over time?

- Using lock washers, thread-locking compounds, or nyloc nuts can prevent loosening due to vibration.

- Can steel nuts be reused?

- Steel nuts can often be reused, but they should be inspected for damage or wear before reapplication.

- What tools are best for tightening?

- Torque wrenches are the preferred tools to ensure precise tightening according to torque specifications.

Applications of Steel Nuts in Construction and Engineering

Steel nuts are widely used in various industries, including construction, automotive, aerospace, and mechanical engineering. In the construction sector, they are essential for connecting structural steel components, securing beams, and assembling trusses. They also play a critical role in machinery assembly, ensuring that components remain securely fastened under dynamic loads.

Other common applications include bridge construction, wind turbine assembly, and fastening critical infrastructure elements. Steel nuts are also used in high-stress environments where resistance to vibration, corrosion, and temperature variations is crucial.

Standards and Evolution of Steel Nuts

The manufacturing and design of steel nuts are governed by strict standards to ensure compatibility and reliability. Key standards include ANSI/ASME B18.2.2 in the U.S., DIN 934 in Europe, and JIS B 1181 in Japan. These standards regulate dimensions, material grades, and threading to maintain uniformity across industries and regions.

Over the years, steel nuts have evolved from basic hand-forged designs to precision-engineered components capable of withstanding extreme stresses. Advanced coatings and treatments, such as zinc plating, galvanization, or black oxide finishes, enhance their durability and resistance to corrosion, making them indispensable in modern engineering applications worldwide.