CAD Blocks categories

3D models

3D models home furniture

home furniture sanitary ware - bathrooms

sanitary ware - bathrooms professional equipment

professional equipment doors and windows

doors and windows people and animals

people and animals plants and trees

plants and trees vehicles - transports

vehicles - transports architectural details

architectural details mechanical - electrical

mechanical - electrical urban planning - civil works

urban planning - civil works safety health construction

safety health construction accessible design

accessible design drawing sheet

drawing sheet signals

signals construction machinery

construction machinery accessories and objects

accessories and objects maps and street maps

maps and street maps

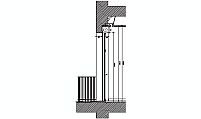

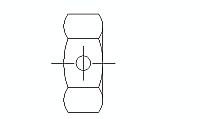

Bottle Trap Plumbing CAD Block with Detailed Features

size: 26 kb

category: electrical, mechanical and HVAC

related categories:

description: detailed front elevation CAD block of a bottle trap plumbing fixture used for sink drainage. The drawing highlights the inlet pipe, outlet pipe, trap body, and cleanout cap for maintenance, with dashed centerlines showing pipe alignment.

file extension: .dwg CAD - AutoCAD software

Features, Dimensions, and Applications of Bottle Trap Plumbing

Functional Components and Features of the Bottle Trap

The bottle trap is an essential plumbing component installed under sinks to facilitate drainage and prevent odors. Its key parts include the following:

- 1. Inlet Pipe: Positioned at the top, this receives wastewater directly from the sink drain.

- 2. Trap Body: The main cylindrical section retains water to create a seal, blocking sewer gases from entering the living space.

- 3. Outlet Pipe: Located on the left side, it directs used water to the main drainage system.

- 4. Cleanout Cap: At the base, this removable threaded cap allows for cleaning and maintenance to remove blockages.

The design combines functionality and compactness, making it suitable for residential and commercial applications. The cylindrical body ensures minimal space usage while maintaining high efficiency.

Dimensions and Standard Sizes for Bottle Traps

Bottle traps are available in standard sizes to fit most sinks and drainage systems. Common dimensions include:

- Inlet Diameter: 1.25 inches (31.75 mm) or 1.5 inches (38.1 mm).

- Outlet Diameter: 1.5 inches (38.1 mm).

- Total Height: Ranges from 6 inches (152 mm) to 10 inches (254 mm), depending on the model.

- Trap Body Diameter: 2 inches (50.8 mm) to 3 inches (76.2 mm).

These dimensions ensure compatibility with most kitchen and bathroom sinks. Bottle traps often come with adjustable pipes to accommodate different installations. Manufacturers adhere to international plumbing standards, such as ASME A112.18.2/CSA B125.2, to guarantee performance and durability.

FAQs About Bottle Trap Plumbing

- What is the purpose of the water seal in the trap?

- The water seal prevents sewer gases from escaping through the sink drain by creating a barrier of standing water in the trap body.

- What materials are commonly used for bottle traps?

- Bottle traps are typically made from brass, stainless steel, or durable plastic (ABS or PVC). These materials are corrosion-resistant and meet plumbing standards.

- How do you maintain a bottle trap?

- The cleanout cap at the base can be unscrewed for easy access, allowing debris and blockages to be removed without dismantling the entire trap.

- Is a bottle trap suitable for all sinks?

- Bottle traps are ideal for bathroom and kitchen sinks with limited space but may not be suitable for high-capacity commercial applications.

- What standards do bottle traps meet?

- In the U.S., bottle traps must comply with ASME and UPC standards to ensure safe and efficient operation in residential and commercial buildings.

Advantages and Benefits of Bottle Trap Plumbing

Bottle traps offer several advantages, including compact design, easy installation, and efficient odor prevention. Their cylindrical body requires minimal space, making them suitable for tight installations under sinks. The cleanout cap simplifies maintenance, reducing downtime and plumbing costs.

Compared to traditional P-traps, bottle traps are more visually appealing, often used in exposed sink designs. Their construction materials, such as chrome-plated brass or polished stainless steel, add to their durability and aesthetics. These features make them a preferred choice for modern bathrooms and kitchens.

History and Evolution of Bottle Trap Plumbing

Bottle traps have been used for decades in plumbing systems, evolving from simple functional designs to highly engineered components. Initially made of cast iron or basic metals, modern versions utilize lightweight and corrosion-resistant materials like ABS plastic and stainless steel.

Advances in manufacturing techniques have improved their durability and versatility. Today, they are widely adopted across the globe, adhering to regional standards like ASME in the U.S. and BS EN 274 in Europe. Manufacturers focus on optimizing performance while maintaining sleek designs for aesthetic and functional integration.