CAD Blocks categories

3D models

3D models home furniture

home furniture sanitary ware - bathrooms

sanitary ware - bathrooms professional equipment

professional equipment doors and windows

doors and windows people and animals

people and animals plants and trees

plants and trees vehicles - transports

vehicles - transports architectural details

architectural details mechanical - electrical

mechanical - electrical urban planning - civil works

urban planning - civil works safety health construction

safety health construction accessible design

accessible design drawing sheet

drawing sheet signals

signals construction machinery

construction machinery accessories and objects

accessories and objects maps and street maps

maps and street maps

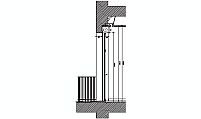

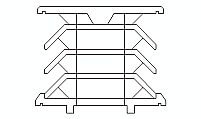

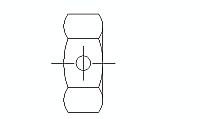

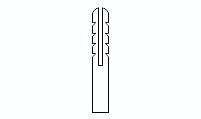

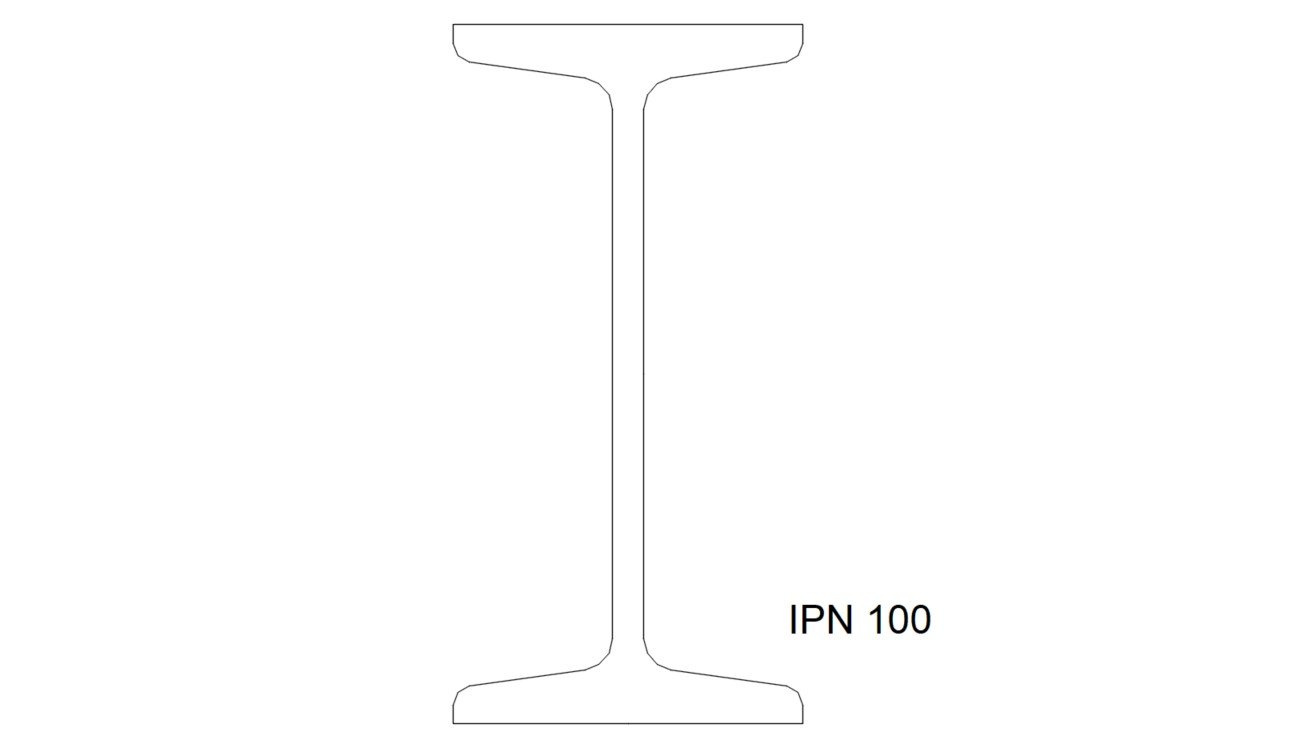

Steel Tapered-flange I-beam | IPN 100 Section

size: 4 kb

category: architectural details

related categories:

description: outline of the IPN 100 steel tapered-flange I-beam, showcasing its cross-sectional geometry, flanges, and web for structural applications.

file extension: .dwg CAD - AutoCAD software

Key Details About the IPN 100 Steel Profile

Detailed Description of IPN 100 Profile

The IPN 100 section is a steel tapered-flange I-beam widely used in construction and engineering projects. Its cross-section features a web connecting two flanges, with the flanges being slightly tapered to optimize material usage and reduce weight. The nominal depth of the IPN 100 is 100 mm, with specific design standards outlined in European structural steel codes. The tapered design makes it suitable for carrying loads effectively while minimizing stress concentrations.

Alternative profiles to the IPN 100 include the American wide-flange beam (W-beam), which is characterized by its parallel flange surfaces. These profiles are commonly employed in structural systems where strength and economy are critical. The W-beam offers similar functionality but differs in geometry and load distribution capabilities.

Dimensions of the IPN 100 Beam

The IPN 100 beam has a nominal depth of 100 mm (3.94 inches) and a flange width of 50 mm (1.97 inches). The web thickness is 5 mm (0.2 inches), and the flange thickness at its thickest point measures 7.4 mm (0.29 inches). These dimensions ensure a balance between load-carrying capacity and material efficiency.

From the attached drawing, the design emphasizes precision, confirming the standard dimensions as prescribed by ISO and EN standards. These measurements are crucial for ensuring compatibility with other structural components and adherence to engineering specifications.

Construction Systems Using IPN Profiles

- What materials are typically used with IPN beams?

- IPN beams are often fabricated using high-strength structural steel, ensuring durability and adaptability to various construction environments.

- How are IPN beams installed?

- IPN beams are typically bolted or welded into structural frameworks, requiring careful alignment and reinforcement for stability.

- Can IPN beams be combined with other profiles?

- Yes, IPN beams are often integrated with rectangular hollow sections, channels, and plates to form composite structures.

- What is the load-bearing capacity of IPN beams?

- The load-bearing capacity depends on the beam's dimensions, material grade, and span length. IPN 100 beams can carry substantial axial and bending loads.

- Are there alternatives to IPN beams for lightweight structures?

- For lightweight structures, L-shaped or C-shaped channels may be considered due to their reduced weight and simpler connections.

Advantages of IPN 100 Over Equivalent Profiles

The tapered-flange design of the IPN 100 beam provides several advantages, such as reduced material usage without compromising strength. This makes it ideal for projects prioritizing efficiency and sustainability. Additionally, its compact size allows for flexibility in construction applications with limited space.

Compared to the W-beam used in the United States, the IPN beam offers a more economical solution for specific load conditions. However, W-beams provide better performance in cases where parallel flange surfaces are needed for uniform load distribution. Both profiles have distinct advantages depending on the engineering requirements.

The equivalent to the IPN 100 in the American standard is the W4x13 wide-flange beam. This profile has a nominal depth of 4.16 inches (106 mm), a flange width of 4 inches (101.6 mm), and a web thickness of 0.23 inches (5.84 mm). The W4x13 weighs 13 pounds per foot (19.37 kg/m) and is commonly used in small-scale structural applications or as secondary framing components in larger assemblies.

In comparison, the IPN 100 has a weight of approximately 8.91 kg/m (5.99 pounds per foot). While lighter than the W4x13, its tapered flanges make it less suitable for certain load-distribution applications where parallel flange beams perform better. The choice between these profiles depends on the specific structural and economic requirements of the project.

History and Evolution of Steel Beams

The IPN series originated in Europe as a standardized approach to structural steel design, ensuring uniformity across various projects. These beams have evolved over decades, incorporating new steel grades and manufacturing techniques to meet modern engineering demands. Their history reflects the growing need for lightweight and efficient construction materials.

In the United States, wide-flange beams (W-beams) serve as the equivalent to IPN profiles. They differ in geometry, with parallel flange surfaces and a focus on load uniformity. Other countries employ similar systems, such as the UB (Universal Beam) in the UK and IPE profiles in international markets. These variations showcase the global evolution of steel beam designs.