CAD Blocks categories

3D models

3D models home furniture

home furniture sanitary ware - bathrooms

sanitary ware - bathrooms professional equipment

professional equipment doors and windows

doors and windows people and animals

people and animals plants and trees

plants and trees vehicles - transports

vehicles - transports architectural details

architectural details mechanical - electrical

mechanical - electrical urban planning - civil works

urban planning - civil works safety health construction

safety health construction accessible design

accessible design drawing sheet

drawing sheet signals

signals construction machinery

construction machinery accessories and objects

accessories and objects maps and street maps

maps and street maps

Prefabricated Hollow Concrete Slab - Free CAD Model

size: 14 kb

category: architectural details

related categories:

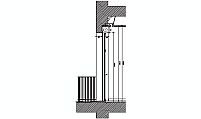

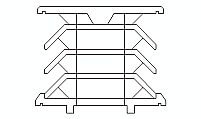

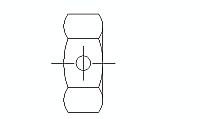

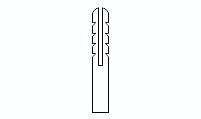

description: prefabricated hollow-core concrete slab with ten internal voids, providing lightweight support in unidirectional flooring systems between beams.

file extension: .dwg CAD - AutoCAD software

Comprehensive CAD Drawing of Prefabricated Hollow Concrete Slab

Overview of Concrete Hollow-Core Slabs in Unidirectional Floor Systems

Concrete hollow-core slabs are prefabricated elements used in unidirectional reinforced concrete floor systems. These slabs serve as permanent formwork and reduce the overall weight of the floor. Placed between beams or semi-beams, they create a modular system that facilitates efficient construction and optimal load distribution.

The hollow cores within the slabs not only lighten the structure but also provide channels for mechanical and electrical installations. This integration enhances the functionality of the building while maintaining structural integrity. The use of hollow-core slabs is prevalent in various construction projects due to their versatility and efficiency.

Regulatory Standards for Concrete Hollow-Core Slabs

Manufacturing of concrete hollow-core slabs must adhere to specific standards to ensure quality and safety. In Europe, the standard UNE-EN 15037-2:2009 specifies requirements for precast concrete products used in floor systems. This standard covers aspects such as dimensions, mechanical resistance, and fire reaction classifications. For instance, slabs must achieve a minimum flexural strength and a fire reaction classification of M1 according to UNE 23727

In the United States, the PCI Manual for the Design of Hollow Core Slabs provides guidelines for the design, manufacture, and installation of these elements. Compliance with these standards ensures that the slabs meet the necessary structural and safety requirements for building construction.

Dimensions and Components of Concrete Hollow-Core Slabs

Concrete hollow-core slabs come in various dimensions to accommodate different construction needs. The typical interaxis distance, or spacing between beams, ranges from 50 cm to 70 cm (19.7 in to 27.6 in), depending on the width of the slabs. Standard heights for these slabs vary between 13 cm and 30 cm (5.1 in to 11.8 in), allowing for flexibility in floor thickness and load requirements.

The CAD block available for download features a slab with a height of 24 cm (9.45 in) and an interaxis distance of 61.5 cm (24.2 in). It includes ten hollow cores, designed to reduce weight and provide space for installations. These dimensions are commonly used in residential and commercial buildings, offering a balance between structural performance and material efficiency.

Advantages of Using Concrete Hollow-Core Slabs

Incorporating concrete hollow-core slabs into floor systems offers several benefits. Their prefabricated nature ensures consistent quality and accelerates construction timelines, as they can be installed quickly on-site. The hollow cores reduce the overall weight of the floor, decreasing the load on the supporting structure and foundations.

Additionally, these slabs provide excellent fire resistance and sound insulation properties, enhancing the safety and comfort of the building. The voids within the slabs can be utilized for routing utilities, contributing to a more organized and efficient building design. Overall, concrete hollow-core slabs are a cost-effective and versatile solution for modern construction projects.

History and Evolution of Concrete Hollow-Core Slabs

The development of concrete hollow-core slabs dates back to the mid-20th century, driven by the need for efficient and economical floor systems in post-war construction. Advances in precast concrete technology allowed for the mass production of these elements, leading to their widespread adoption in residential and commercial buildings.

Over the years, improvements in manufacturing processes and design methodologies have enhanced the performance and versatility of hollow-core slabs. Today, they are integral to sustainable construction practices, offering solutions that meet stringent energy efficiency and environmental standards. The evolution of these slabs reflects the construction industry's commitment to innovation and quality.