CAD Blocks categories

3D models

3D models home furniture

home furniture sanitary ware - bathrooms

sanitary ware - bathrooms professional equipment

professional equipment doors and windows

doors and windows people and animals

people and animals plants and trees

plants and trees vehicles - transports

vehicles - transports architectural details

architectural details mechanical - electrical

mechanical - electrical urban planning - civil works

urban planning - civil works safety health construction

safety health construction accessible design

accessible design drawing sheet

drawing sheet signals

signals construction machinery

construction machinery accessories and objects

accessories and objects maps and street maps

maps and street maps

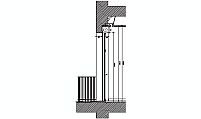

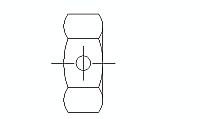

Steel Nut Top View - DWG CAD Drawing

size: 6 kb

category: architectural details

related categories:

description: Top view CAD representation of a steel nut, displaying a circular threaded opening and hexagonal outer shape, commonly used in various engineering applications.

file extension: .dwg CAD - AutoCAD software

Specifications and Applications of Steel Nuts

Design and Structure of Steel Nuts

Steel nuts are fundamental components in mechanical assemblies, designed to fasten parts together securely. The top view reveals a hexagonal outer profile, facilitating wrench application from multiple angles, and a central circular threaded hole that accommodates corresponding bolts. This configuration ensures uniform force distribution and reliable joint integrity.

In addition to the standard hexagonal shape, variations such as flange nuts—which include an integrated washer-like base—are utilized to distribute pressure over a larger area, reducing the risk of damage to the connected surfaces. The choice of nut type depends on specific application requirements, including load conditions and environmental factors.

International Standards and Dimensions

Steel nuts are manufactured in accordance with various international standards to ensure compatibility and performance. In the United States, the ANSI/ASME B18.2.2 standard specifies dimensions for hex nuts. European countries adhere to the DIN 934 standard, while Japan follows the JIS B 1181 specification. These standards define parameters such as thread pitch, across-flats distance, and nut height, ensuring interoperability across different regions and industries.

Common metric sizes include M6, M8, and M10, with corresponding across-flats dimensions of 10 mm, 13 mm, and 17 mm, respectively. In imperial measurements, typical sizes are 1/4 inch, 5/16 inch, and 3/8 inch, with across-flats dimensions of 0.438 inches, 0.500 inches, and 0.562 inches, respectively. Adherence to these standardized dimensions is crucial for ensuring the proper fit and function of nuts in mechanical assemblies.

Material Properties and Coatings

Steel nuts are typically fabricated from carbon or alloy steel, offering a balance between strength and ductility. To enhance corrosion resistance, especially in outdoor or marine environments, these nuts may undergo surface treatments such as zinc plating, galvanization, or application of black oxide finishes. These coatings provide a protective barrier against oxidation and environmental degradation.

For applications requiring higher corrosion resistance, such as in chemical processing or coastal construction, stainless steel nuts are preferred due to their inherent resistance to rust and staining. The selection of material and coating is determined by factors including environmental exposure, mechanical load requirements, and longevity considerations.

Applications in Engineering and Construction

Steel nuts are integral to a wide range of applications in engineering and construction. They are employed in the assembly of structural steel frameworks, securing beams and columns in buildings and bridges. In mechanical engineering, they are used to fasten components in machinery, vehicles, and equipment, ensuring operational stability and safety.

Beyond structural applications, steel nuts are also utilized in the installation of electrical panels, plumbing systems, and HVAC units, where secure and reliable fastening is essential. Their versatility and reliability make them indispensable in both heavy-duty industrial contexts and everyday household uses.

Evolution and Technological Advancements

The development of steel nuts has evolved significantly since their inception. Early fastening methods relied on simple wooden or metal wedges, but the advent of threading technology in the 18th century revolutionized mechanical assembly. The standardization of thread forms and nut dimensions in the 20th century facilitated mass production and global interoperability of components.

Recent advancements include the development of self-locking nuts, which resist loosening under vibration, and the use of advanced materials such as titanium alloys for applications requiring high strength-to-weight ratios. Ongoing research focuses on enhancing performance through improved materials, coatings, and design innovations to meet the ever-increasing demands of modern engineering and construction.