CAD Blocks categories

3D models

3D models home furniture

home furniture sanitary ware - bathrooms

sanitary ware - bathrooms professional equipment

professional equipment doors and windows

doors and windows people and animals

people and animals plants and trees

plants and trees vehicles - transports

vehicles - transports architectural details

architectural details mechanical - electrical

mechanical - electrical urban planning - civil works

urban planning - civil works safety health construction

safety health construction accessible design

accessible design drawing sheet

drawing sheet signals

signals construction machinery

construction machinery accessories and objects

accessories and objects maps and street maps

maps and street maps

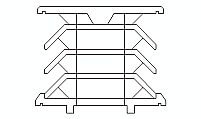

Oil-Filled Transformer CAD Block with Detailed Views

size: 60 kb

category: electrical, mechanical and HVAC

related categories:

description: CAD drawing of an oil-filled transformer with labeled sections for switchgear space, transformer clearance, ventilation grille, transformer core, cable management, and oil collection basin.

file extension: .dwg CAD - AutoCAD software

Detailed Features, Parts, and Functionality of Oil-Filled Transformers

Detailed Parts of the Oil-Filled Transformer

The CAD drawing of the oil-filled transformer includes six key labeled parts, each critical to its design and functionality:

- 1. Space for Switchgear: A dedicated area measuring 3.95 m (155.51 inches) in width and 2.42 m (95.28 inches) in height. This section accommodates the electrical switchgear for transformer control and protection.

- 2. Transformer Clearance: This clearance, at 2.58 m (101.57 inches), ensures safe installation and proper ventilation of the transformer.

- 3. Ventilation Grille: Located on the transformer housing, it measures 2.62 m (103.15 inches) in height and provides essential cooling to maintain optimal temperatures.

- 4. Transformer Core: The core itself measures approximately 2.50 m (98.43 inches) and is housed centrally within the tank for efficient operation.

- 5. Free Space for Cable Management: A reserved area measuring 2.58 m (101.57 inches) to facilitate organized cabling and reduce maintenance issues.

- 6. Oil Collection Basin: The basin below the transformer collects potential oil leaks and measures 2.58 m (101.57 inches) in width for environmental compliance.

This CAD block includes front, side, and top views, adhering to global transformer manufacturing standards and design guidelines.

Dimensions and Size Details

The oil-filled transformer depicted in the CAD block is designed with dimensions that ensure efficiency and compliance with industry standards. The overall dimensions are 2.58 m (101.57 inches) in depth, 3.95 m (155.51 inches) in width, and 2.62 m (103.15 inches) in height. These proportions make it suitable for medium-voltage applications in industrial and utility environments.

The transformer housing, including the ventilation grille, and clearance spaces, is designed for easy installation and maintenance. Each section of the design follows international safety guidelines, such as those from ANSI/IEEE and IEC, to ensure compatibility and performance across multiple regions and industries.

FAQs on Oil-Filled Transformer Construction

- Why is space for switchgear essential?

- The dedicated switchgear space ensures easy installation and control of the transformer. It also provides safe access for circuit breakers and protective devices.

- What role does the ventilation grille play?

- The ventilation grille allows heat dissipation from the transformer core and oil, maintaining stable operating temperatures and preventing overheating.

- What materials are used for the transformer core?

- The core is typically made of laminated silicon steel to reduce eddy current losses and enhance magnetic efficiency.

- How is oil leakage managed?

- The oil collection basin is designed to contain any leaks, protecting the environment and ensuring compliance with environmental regulations.

- What standards govern transformer design?

- Oil-filled transformers must adhere to ANSI/IEEE and IEC standards, ensuring safety, efficiency, and durability in different operating environments.

Advantages of Oil-Filled Transformers

Oil-filled transformers are widely used due to their high efficiency and durability. The oil serves as both a coolant and an insulator, ensuring that the transformer can handle heavy loads without overheating. This design provides superior performance compared to dry-type transformers in high-voltage applications.

The CAD block’s detailed dimensions and labeled parts make it a valuable resource for engineers and architects. It supports accurate planning and integration into designs, ensuring compliance with regulatory standards and enhancing project outcomes.

History and Evolution of Oil-Filled Transformers

Oil-filled transformers have been a cornerstone of power distribution since the late 19th century. Early designs focused on basic insulation, but modern transformers incorporate advanced cooling systems and environmentally friendly oils to improve efficiency and reduce environmental impact.

Today, leading manufacturers like ABB, Siemens, and GE design transformers that meet international standards. They are widely used in power grids, industrial facilities, and renewable energy projects worldwide, demonstrating their adaptability and reliability in evolving energy landscapes.