CAD Blocks categories

3D models

3D models home furniture

home furniture sanitary ware - bathrooms

sanitary ware - bathrooms professional equipment

professional equipment doors and windows

doors and windows people and animals

people and animals plants and trees

plants and trees vehicles - transports

vehicles - transports architectural details

architectural details mechanical - electrical

mechanical - electrical urban planning - civil works

urban planning - civil works safety health construction

safety health construction accessible design

accessible design drawing sheet

drawing sheet signals

signals construction machinery

construction machinery accessories and objects

accessories and objects maps and street maps

maps and street maps

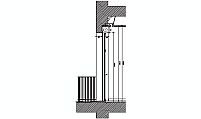

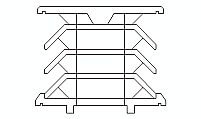

Reinforced Concrete Beam Rebar Design

size: 11 kb

category: architectural details

related categories:

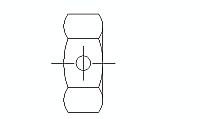

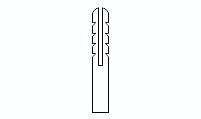

description: A technical drawing of a reinforced concrete beam rebar arrangement, showing precise dimensions, spacings, and detailed specifications for construction.

file extension: .dwg CAD - AutoCAD software

Structural Rebar Details for Concrete Beams

Beam Rebar Configuration

The reinforced concrete beam in the diagram illustrates a detailed arrangement of longitudinal and transverse reinforcement. Longitudinal bars are carefully positioned to counteract tensile stresses, while stirrups provide resistance against shear forces. This configuration enhances the structural integrity of the beam under heavy loads and dynamic forces.

Other rebar configurations, such as those used in cantilever beams or continuous beams, often adapt similar principles with variations in the number of bars or spacing. These configurations are optimized to handle specific load conditions, making them versatile for diverse structural applications.

Dimensions and Spacing

The rebar in the diagram includes diameters of 16 mm, 12 mm, and 6 mm. Beam widths are specified at 30x30 cm and 30x50 cm, while column sections measure 30x30 cm. The stirrups have a diameter of 6 mm and are spaced 16 cm or 18 cm apart, depending on the type of stress the beam is subjected to. This precise arrangement ensures structural efficiency and stability.

Stirrups play a crucial role in reinforced concrete beams by resisting shear forces and holding the longitudinal bars in position. They prevent the concrete from cracking under diagonal tension and ensure the beam's durability by distributing loads evenly. By maintaining the integrity of the rebar cage, stirrups contribute to the overall stability and load-bearing capacity of the beam, making them indispensable in structural design.

Construction Techniques

Reinforced concrete beams are built using a systematic process starting with formwork preparation. Rebar cages are assembled and secured, ensuring accurate positioning for tensile and shear resistance. Concrete is poured carefully, and vibrators are used to eliminate air pockets and achieve a dense, compact mix.

To ensure durability, the curing process plays a critical role. Proper curing helps the concrete reach its designed strength and ensures that the bond between the steel and concrete remains strong, protecting the beam against environmental factors and long-term wear.

Advantages of Rebar

Reinforced concrete beams excel in providing superior tensile and compressive strength, making them a cornerstone of modern construction. Rebar prevents cracks from propagating, ensuring that the beam can handle high loads while maintaining structural integrity over time.

Compared to alternative materials like timber or steel beams, reinforced concrete is more cost-effective and versatile. It can be used in a variety of applications, from residential buildings to large-scale infrastructure, adapting to diverse architectural and engineering needs.

Origins and Evolution

The invention of reinforced concrete in the 19th century revolutionized construction by combining concrete's compressive strength with steel's tensile strength. This innovation allowed for the creation of stronger, more versatile structures that could withstand complex load conditions.

Over time, advancements in material science and engineering have improved the efficiency of reinforced concrete. Modern techniques, such as pre-stressing and post-tensioning, have further enhanced its load-bearing capabilities, ensuring that reinforced concrete remains a vital element in global construction practices.