CAD Blocks categories

3D models

3D models home furniture

home furniture sanitary ware - bathrooms

sanitary ware - bathrooms professional equipment

professional equipment doors and windows

doors and windows people and animals

people and animals plants and trees

plants and trees vehicles - transports

vehicles - transports architectural details

architectural details mechanical - electrical

mechanical - electrical urban planning - civil works

urban planning - civil works safety health construction

safety health construction accessible design

accessible design drawing sheet

drawing sheet signals

signals construction machinery

construction machinery accessories and objects

accessories and objects maps and street maps

maps and street maps

Wood Guardrail Attachment Design in DWG Format

size: 32 kb

category: worker safety systems

related categories:

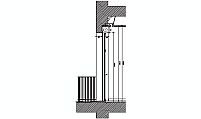

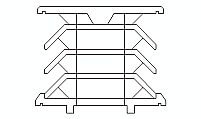

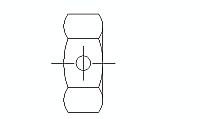

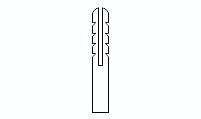

description: the image shows a CAD drawing of a temporary wooden guardrail system designed for construction safety. The guardrail is 1.5 inches thick and securely attached to a metal post shore with a diameter of 2 to 3 inches. It uses robust clamps to provide stability. Both elevation view and plan view illustrate the precise connection points for reliable and secure assembly.

file extension: .dwg CAD - AutoCAD software

Detailed CAD Drawings of Wood Guardrail Attachment

Guardrail Components and Dimensions

This CAD block illustrates a temporary wooden guardrail built for construction safety. The system includes a 1.5-inch thick wooden rail connected to a metal post shore using durable clamps for secure assembly. The 2-3 inch diameter post ensures compatibility with typical support structures, enabling reliable installation in varied environments. The design is practical and adaptable for on-site use.

The guardrail's height complies with OSHA regulations in the United States, requiring a standard height of 42 inches (3.5 feet or approximately 1.07 meters). The clamp positioning prevents unwanted movement, ensuring the structure remains stable under pressure and provides consistent safety performance in construction areas.

Regulatory Standards and Requirements

In the United States, OSHA 1926.502(b) mandates guardrails to be at least 42 inches high and capable of withstanding 200 pounds of force. Components must be free of structural defects to ensure safety. Other international standards, such as Canada's CSA Z259 and the UK's BS EN 13374, provide similar guidelines for consistent safety practices in construction.

Additional measures include mid-rails and toe boards to prevent tools or debris from falling. In Germany (DIN EN 13374) and France, regulations also emphasize durable materials capable of withstanding environmental exposure. Regular inspections are crucial to maintaining performance and compliance with safety standards worldwide.

Common Questions About Guardrail Attachments

- How is the guardrail attached to the metal post?

- The guardrail is secured to the post using heavy-duty clamps that provide a firm and stable connection. The clamps are adjustable to accommodate the 2-3 inch diameter of the metal post shore, ensuring compatibility with various setups. This attachment method is quick, efficient, and ensures a secure connection for enhanced safety.

- What tools are required for installation?

- Installation typically requires basic tools like wrenches or screwdrivers, depending on the fasteners used in the clamps. These tools ensure that the clamps are tightened securely around the wooden rail and the metal post shore. The simplicity of the tools makes the system easy to assemble on-site without specialized equipment.

- Is the guardrail system reusable?

- Yes, the system is fully reusable. The clamps and wooden rails can be disassembled and used on other construction sites. Proper maintenance, including inspection for wear or damage, ensures the longevity of the components and their suitability for future projects.

- What materials can be used with this system?

- While the system shown uses wood, it is also compatible with other materials such as composite boards or treated lumber. The key requirement is that the material should match the specified thickness and possess adequate strength to handle the expected load.

- Does this guardrail system resist weathering?

- Wooden components should be treated to resist decay, and clamps must be made of corrosion-resistant materials, such as galvanized steel. Regular maintenance is essential to ensure the system remains durable and effective when exposed to outdoor elements over time.

Variants and Alternative Systems

There are various alternative systems to the wooden guardrail attachment shown. One popular variant includes adjustable clamps that allow for attachment to posts of varying diameters, increasing compatibility with diverse setups. Another variation incorporates pre-drilled guardrails, which streamline the installation process and reduce on-site preparation time.

Steel and aluminum guardrails are frequently used in environments where higher durability is required, such as areas with heavy foot traffic or adverse weather conditions. Mesh panels are sometimes added to provide enhanced protection by preventing objects from falling through the openings. Modular systems offer additional flexibility, allowing for height adjustments and reconfigurations as needed for specific projects.

Benefits of Using Guardrail Systems

Guardrail systems like this provide essential safety by preventing falls, ensuring compliance with construction safety standards. The wooden design is economical and widely available, making it a popular choice for temporary installations. The use of clamps enhances adaptability and simplifies the setup, reducing time and labor costs during installation.

Additionally, guardrails contribute to a safer work environment, minimizing the risk of injuries and legal liabilities. They are versatile and can be used in various types of construction, from residential to large-scale commercial projects. Installing a reliable guardrail system not only ensures worker safety but also improves overall project efficiency.