CAD Blocks categories

3D models

3D models home furniture

home furniture sanitary ware - bathrooms

sanitary ware - bathrooms professional equipment

professional equipment doors and windows

doors and windows people and animals

people and animals plants and trees

plants and trees vehicles - transports

vehicles - transports architectural details

architectural details mechanical - electrical

mechanical - electrical urban planning - civil works

urban planning - civil works safety health construction

safety health construction accessible design

accessible design drawing sheet

drawing sheet signals

signals construction machinery

construction machinery accessories and objects

accessories and objects maps and street maps

maps and street maps

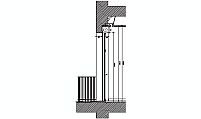

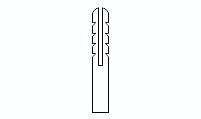

Detailed Design of Temporary Safety Rail

size: 112 kb

category: worker safety systems

related categories:

description: The image shows a CAD model of temporary construction guardrail with detailed assembly. Key elements include the PVC pipe placeholder, beam formwork adapter, and the attachment points to formwork. The total height is 3'-11.24" (1.20 m), with intermediate section heights of 2'-6.35" (0.77 m) and 11.56" (0.29 m). The lower attachment extends 10.40" (0.26 m) for secure positioning.

file extension: .dwg CAD - AutoCAD software

Understanding the Temporary Safety Rail Design and Usage

Temporary Safety Rail Design Overview

The temporary safety rail is a crucial safety feature in construction, designed to prevent falls and protect workers during various project phases. It includes a vertical rail, intermediate supports, and a secure base attachment system. The connection to formwork is achieved through placeholders and adapters that ensure stability and prevent dislodging during use. This design is practical, efficient, and adaptable to changing site conditions, making it essential for worker protection.

Compared to other solutions, such as scaffolding guardrails, this safety rail offers enhanced flexibility. Its modular design allows for quick assembly and disassembly, catering to projects that require frequent adjustments or relocations. This makes it a preferred choice for contractors seeking reliable and cost-effective safety measures.

Dimensions and Technical Specifications

The temporary safety rail in this technical drawing has carefully optimized dimensions for construction safety. Its total height is 3'-11.24" (1.20 m), with intermediate section heights of 2'-6.35" (0.77 m) and 11.56" (0.29 m). The base attachment extends 10.40" (0.26 m), ensuring a secure fit to formwork and stability during use. These dimensions are designed to comply with safety regulations and fit standard construction setups.

Each component complements the system's function, ensuring a balance between safety and practicality. The rail's compatibility with modern and traditional construction methods makes it versatile and suitable for a variety of building applications.

Regulatory Requirements for Temporary Safety Rails

United States (OSHA): Temporary safety rails must comply with OSHA 1926.502 standards. The minimum height requirement is 42 inches (1.07 m), with a tolerance of ±3 inches. Rails must be able to withstand a force of 200 pounds (90.7 kg) applied in any direction. A midrail is required halfway between the top rail and the working surface. Toe boards are mandatory to prevent falling objects. Rails should be secured to withstand displacement, and overhangs or cantilevers must not create a tripping hazard.

Canada: According to the Canadian Center for Occupational Health and Safety (CCOHS), safety rails must have a height of 36–42 inches (0.91–1.07 m). They must support a load of 125 pounds (56.7 kg) applied horizontally at the top rail. Midrails and toe boards are required. Installation must ensure stability and resistance to lateral forces, and connectors must comply with CSA standards for building safety.

United Kingdom: The UK’s Working at Height Regulations (WAHR) require guardrails with a minimum height of 950 mm (37.4 inches). Intermediate rails must ensure no gap exceeds 470 mm (18.5 inches). The system must withstand a horizontal force of 50 kg (110 pounds). Guardrails must be securely fixed to prevent dislodging and should be checked regularly to maintain compliance.

Japan: Safety regulations in Japan mandate guardrails with a minimum height of 90 cm (35.4 inches). Midrails are required to divide the vertical space evenly. Temporary rails must withstand a force of 100 kg (220 pounds), and connections must be secured to ensure stability. Toe boards are recommended for elevated work areas to reduce the risk of falling objects.

Germany: According to DIN EN 13374, safety rails must have a minimum height of 1.0 m (39.4 inches) and include midrails or infill to prevent gaps exceeding 47 cm (18.5 inches). The rails must withstand a force of 100 kg (220 pounds) applied horizontally. Temporary rails must be firmly attached to prevent displacement, and materials must meet TÜV safety certifications.

France: The French Labor Code (Code du Travail) requires guardrails with a minimum height of 1.1 m (43.3 inches). Midrails are mandatory, ensuring no gap larger than 500 mm (19.7 inches). Rails must resist a force of 100 kg (220 pounds). Installation guidelines stress the importance of stability and regular inspection to ensure ongoing compliance with safety standards.

Common Questions About Temporary Safety Rail

- How does the temporary safety rail attach to formwork?

- The rail attaches securely using placeholders and beam adapters. These components create a tight connection to the formwork, ensuring the rail remains stable during concrete pours. This attachment system minimizes movement, providing a safe and reliable solution for fall protection on-site.

- Can the temporary safety rail be reused?

- Yes, the temporary safety rail is reusable, making it a cost-effective and sustainable solution. Its modular design allows for disassembly and relocation across projects. This feature reduces waste and enhances the system's long-term value, especially for large-scale construction.

- What materials are used in its construction?

- The rail is primarily constructed of galvanized steel for durability and PVC placeholders for lightweight handling. These materials ensure the rail withstands heavy-duty use while remaining easy to install and transport.

- Does this safety rail meet construction safety standards?

- Yes, it complies with OSHA and ANSI regulations, ensuring its suitability for construction projects. These standards validate its performance in providing fall protection and structural reliability.

- Can the rail adapt to different heights?

- Yes, the modular design of the rail allows height adjustments. This feature makes it versatile and capable of meeting specific site requirements, from low-rise applications to elevated construction work.

Evolution and Global Variants of Safety Rails

The temporary safety rail has undergone significant evolution, from basic wooden barriers to modern systems made of galvanized steel and reinforced PVC. These materials have improved durability, ease of use, and safety compliance, adapting to the needs of contemporary construction practices.

Globally, similar systems are known as edge protection barriers in Europe and scaffold guardrails in Asia. Despite regional differences, these systems share a common goal: to protect workers and prevent falls. This universal requirement continues to drive innovation in safety rail design worldwide.