CAD Blocks categories

3D models

3D models home furniture

home furniture sanitary ware - bathrooms

sanitary ware - bathrooms professional equipment

professional equipment doors and windows

doors and windows people and animals

people and animals plants and trees

plants and trees vehicles - transports

vehicles - transports architectural details

architectural details mechanical - electrical

mechanical - electrical urban planning - civil works

urban planning - civil works safety health construction

safety health construction accessible design

accessible design drawing sheet

drawing sheet signals

signals construction machinery

construction machinery accessories and objects

accessories and objects maps and street maps

maps and street maps

Temporary Clamp Protection CAD Design

size: 40 kb

category: worker safety systems

related categories:

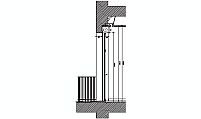

description: The image shows a CAD design featuring a clamp-on safety railing system with temporary masonry steps. The steps have a tread depth of 10.63 inches (27 cm) and a riser height of 6.69 inches (17 cm). The design ensures secure installations during construction with detailed dimensions for precise assembly.

file extension: .dwg CAD - AutoCAD software

Detailed Safety Solutions with Temporary Clamp Protection

Components and Dimensions of Temporary Clamp Protection

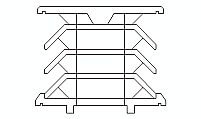

This CAD block illustrates a temporary clamp-on protection system, which is a critical element for ensuring safety during construction. It features a clamp-on safety railing that attaches securely to masonry or temporary structures, providing robust fall protection. The system includes temporary masonry steps with precise dimensions: a tread depth of 10.63 inches (27 cm) and a riser height of 6.69 inches (17 cm). These dimensions ensure the steps meet accessibility and safety requirements. The overall height of the assembly is 10'-5.06", with a total length of 11'-0.36", providing ample clearance for secure access and stability.

The design of this system prioritizes both functionality and compliance with international safety standards. Its temporary steps and clamp-on railings are specifically engineered for quick installation, reducing the risk of accidents during construction. The clamps are strategically positioned to hold the railings securely, ensuring no movement or slippage occurs. The materials used in this system, such as durable metal for the railings and treated masonry steps, enhance its overall reliability. This setup is ideal for short-term safety needs in a variety of construction scenarios.

Regulatory Standards for Clamp Protection Systems

In the United States, OSHA 1926.451(g) establishes guidelines for temporary fall protection systems, including guardrails and clamp-on safety railings. These systems must withstand a minimum force of 200 pounds applied downward or outward to ensure they remain secure. The steps must adhere to dimensional stability requirements for safe and accessible use. Temporary setups like these are vital for meeting compliance standards while maintaining flexibility for various project conditions.

Other global standards include Canada's CSA Z259, which emphasizes fall arrest systems, and the United Kingdom's BS EN 13374, which outlines requirements for temporary edge protection systems. In Germany (DIN EN 13374) and France, similar specifications focus on durability and material resilience. Regular inspections of all components are mandatory to ensure that systems remain functional and comply with regulations. These standards aim to minimize risks and enhance worker safety in construction environments worldwide.

Common Questions About Temporary Clamp Protection

- What is a clamp-on safety railing?

- A clamp-on safety railing is a temporary fall protection system designed to attach securely to stairs, platforms, or edges using clamps. It ensures worker safety by creating a sturdy barrier to prevent falls during construction or maintenance tasks. The railing can be easily installed and removed, making it ideal for short-term projects where permanent railings are unnecessary or impractical.

- What are the dimensions of the temporary steps?

- The temporary steps in this system have a tread depth of 10.63 inches (27 cm) and a riser height of 6.69 inches (17 cm). These measurements comply with construction safety standards for accessibility and stability. The steps are wide enough to allow safe passage while maintaining compactness, making them suitable for limited workspace areas.

- How much force can the railing withstand?

- The clamp-on safety railing is designed to withstand a force of 200 pounds applied in any direction, ensuring compliance with OSHA 1926.451(g) guidelines. This level of resistance guarantees that the railing remains stable under normal working conditions, including potential impacts or sudden pressure from workers or equipment.

- Are these systems reusable?

- Yes, temporary clamp protection systems are fully reusable, making them a cost-effective solution for multiple construction projects. They can be easily disassembled, inspected, and reassembled for use on new job sites. Regular maintenance and inspection are critical to ensure all components, including clamps and railings, remain functional and safe for reuse.

- What materials are used in these systems?

- These systems are typically constructed from durable metals such as steel or aluminum, which provide strength and resistance to corrosion. The steps are often made from treated masonry or reinforced materials to withstand heavy loads. These materials ensure the system is both robust and weather-resistant, suitable for a wide range of environments and conditions.

Variants and Alternative Systems

Temporary clamp protection systems come in multiple configurations to suit diverse construction needs. One variant includes adjustable railings that accommodate platforms or stairs of varying dimensions, offering flexibility. Another option integrates non-slip surfaces into the steps for enhanced worker safety, particularly in wet or slippery conditions. These adaptations make the systems highly versatile and reliable for specific requirements.

Alternative solutions may include prefabricated stairs with integrated guardrails or fixed edge protection systems designed for long-term use. Some setups feature mesh panels between railings to prevent objects or tools from falling. These alternatives are well-suited for projects where enhanced safety measures or durability are necessary, such as high-traffic areas or permanent installations.

Benefits of Temporary Clamp Protection Systems

Temporary clamp protection systems offer a practical solution for preventing falls and ensuring worker safety during construction or maintenance. Their clamp-on design allows for quick and efficient installation, reducing setup time and labor costs. These systems provide reliable fall protection while maintaining flexibility for short-term projects where permanent structures are unnecessary.

By complying with international safety standards, these systems minimize workplace risks and improve overall productivity. They are cost-effective due to their reusability and adaptability to various environments. Their lightweight and modular components also make them easy to transport and store, further enhancing their practicality for construction professionals.